In this study, separator rejects of a closed circuit cement tube milling were dry ground in a 10l pilot scale vertical stirred mill. Tests were done as open and closed circuit.

WhatsApp: +86 18037808511

Compare this product Remove from comparison tool {{productPushLabel}} {{#if }} ... Ball mill is widely used to process cement, silicate product, new building materials, fireproof materials, ... Compare this product Remove from comparison tool. See the other products Henan LIMING Heavy Industry Science and Technology. roller ...

WhatsApp: +86 18037808511

of a cement powder and is closely linked to cement performance. Presently, the only relevant standard method is ASTM C11596, a turbidimetric method for determining fineness (Standard Test Method for Fineness of Portland Cement by the Turbidimeter ASTM C115). This method is limited in scope, however, with a lower size detection limit of µm.

WhatsApp: +86 18037808511

Zestimate® Home Value: 1,600,000. 2132 Burnt Mill Rd, Tustin, CA is a single family home that contains 2,825 sq ft and was built in 1989. It contains 5 bedrooms and 3 bathrooms. The Zestimate for this house is 1,599,900, which has decreased by 77,940 in the last 30 days. The Rent Zestimate for this home is 5,600/mo, which has decreased by 29/mo in the last 30 days.

WhatsApp: +86 18037808511

For a ball mill grinding OPC to a fineness of 3200 to 3600 cm2/g (Blaine) the cost of wear parts (ball, liners and mill internals) is typically EUR per ton of cement. For an OK mill grinding a similar product, the cost of wear parts depends on the maintenance procedures, whether hardfacing is applied.

WhatsApp: +86 18037808511

processing units are crushers unit, raw mill, homogenizing plant, kiln system, cement mill and packing plant. Here, dry production process is used because energy consumption is less and running cost is also lower compared to other process. The raw materials used are in the following compositions; limestone 9597% and laterite 35%.

WhatsApp: +86 18037808511

and vertical roller mill, VRM [35]. Among these devices, VRM plays an important role in cement, accounting for more than 55% of China's cement raw meal market [6], and its performance directly affects the cost of producing cement. VRM has the functions of grinding and powder selection, including a grinding unit and an air classifier ...

WhatsApp: +86 18037808511

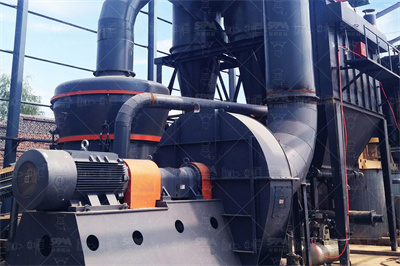

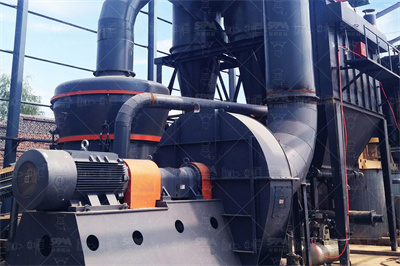

As the speed increases, the airflow side pressure is generated by the blades and the centrifugal force of the spreading plate increases. The particle size will become smaller. The cement separator is also called cement mill separator. It is a crucial cement making machine in cement grinding plant. Cyclone air separator is a kind of efficiency ...

WhatsApp: +86 18037808511

PDF | On May 13, 2021, Elshan Moradkhani and others published Intelligent Modeling of Cement Plant Mill Unit Using Artificial Neural Networks and Real Data | Find, read and cite all the research ...

WhatsApp: +86 18037808511

The performance of grinding media in a ball mill is also measured in terms of its wear rate. Abrasive ores such as gold and copper produce high wear rates of about 120µm/hr [74]. The wear of ...

WhatsApp: +86 18037808511

An improved differential evolutionary cement mill operation index decision algorithm based on constraint control and selection strategy is proposed to addr ... The power consumption comparison experiment results are shown in Fig. 12. Fig. 12. Comparison of energy consumption after cement mill optimization and historical average energy consumption.

WhatsApp: +86 18037808511

Cement Mill Feeding size: ≤20≤25mm Production capacity: /h Processing Materials: cement clinker, limestone, bauxite, aluminum hydroxide, etc. The cement mill (cement ball mill ) ... Compare this product Remove from comparison tool

WhatsApp: +86 18037808511

Vertical roller mills (VRM) are widely used to grind, dry, and select powders from various materials in the cement, electric power, metallurgical, chemical, and nonmetallic ore industries. For the sectors above, the VRM is a powerful and energyintensive grinding field [1], [2]. It is used to grind slag, nonmetallic ore, and other block and ...

WhatsApp: +86 18037808511

As per European cement research academy's project "Future grinding technologies", out of 1036 orders of grinding mills in 5 years, 58% were for Vertical Roller mill and 40% were for Ball Mill + HPGR circuit. Hence Ball Mill VRM are major technologies in cement grinding. Their technological comparison is done beneath [8]. 4.

WhatsApp: +86 18037808511

cutting mill TG5000. horizontal for cement mobile. Rotational speed: 10 rpm. Motor power: 403 kW. Sound pressure: 77, 96, 117 dB. The TG5000 tub grinder from Vermeer is your machine for powerful processing in a convenient package, with a 540 hp (403 kW) engine and optional loader with grapple. With the new Series III duplex drum, the TG5000 ...

WhatsApp: +86 18037808511

The following presents a comparison of the two mill systems with reference to these issues. Grinding process The grinding process in ball mills and vertical roller mills differ fundamentally. In a ball ... serious challenge to obtain a good performance of a vertical roller mill in cement grinding. Today, however, the OK mill has become an ...

WhatsApp: +86 18037808511

In this study, in order to evaluate and compare the performances of these cement grinding technologies, industrial scale data were collected from HPGRball mill, VRM, Horomill and multichamber ...

WhatsApp: +86 18037808511

A 10 MW cement mill, output 270 tonnes per hour. A cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

WhatsApp: +86 18037808511

Cement Grinding Aids. ₹ 72/ Kilogram Get Latest Price. We are highly attributed in market for providing to our patrons a finest quality of Cement Grinding Aids. These products are extensively used in commercial industry for various purposes. We present these ranges of products to the patrons in safe and varied packaging for ease of consumers.

WhatsApp: +86 18037808511

Nowadays, ball mills are widely used in cement plants to grind clinker and gypsum to produce cement. The research focuses on the mill speed as well as air classifier speed effect on the two ...

WhatsApp: +86 18037808511

In cement mills, ventilation is a critical key for maintaining temperature and material transportation. ... BNN could accurately predict the measuring pressure before and after the mill fan, with R 2 = A comparison between BNN outcomes and random forest/support vector regression, R 2 <, approved this newly developed model's ...

WhatsApp: +86 18037808511

Abstract. Ball mills for fine grinding cement clinker and additives are widely used around the world. To improve the efficiency of a ball grinding the ball mills are transferred in closed circuit ...

WhatsApp: +86 18037808511

Cement production is one of the most energyintensive manufacturing industries, and the milling circuit of cement plants consumes around 4% of a year's global electrical energy production. It is ...

WhatsApp: +86 18037808511

In comparison with ball mills, vertical roller mills can achieve an energy saving of up to 30%, horizontal roller mills up to 35%, and HPRM's up to 50% [5], [6]. This comparison, however, reflects the power consumption of the mill only and does not include air classifier and auxiliary equipment like conveyors and dust collectors.

WhatsApp: +86 18037808511

Abstract. Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding. The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment in ...

WhatsApp: +86 18037808511

The raw material preparation system of the 2 500 t/d cement production line can adopt the vertical mill with the disc diameter of 3 400 mm as the main grinding machine. When the grinding particle size is less than 60 mm, the fineness of the finished product is 16%, and the moisture content of the finished product is %.

WhatsApp: +86 18037808511

The power ingesting of a grinding process is 5060% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills. The process variables in cement grinding process using VRM are strongly nonlinear and having large time

WhatsApp: +86 18037808511

The difference between ball mill and vertical mill in cement grinding Over the last three decades the vertical roller mill has become the preferred ball mill for grinding of raw materials. The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system.

WhatsApp: +86 18037808511