hindering the screening and crushing process as well as processing costs. An example of changes in existing technological systems resulting in lower costs is the Mount Isa processing plant [1]. The Mount Isa processing plant started working with a grinding system based on twostage crushing in jaw crushers and grinding in rod mills.

WhatsApp: +86 18037808511

Comchambered with the design of Φ × 13m threechamber ball mill, the design process of ball mill is described in detail. ... and play t he role of crushing and grinding, so .

WhatsApp: +86 18037808511

It is less efficient for fine grinding. For fine grinding, the hammer mill is most efficient. On farms where a large herd of livestock is kept, it may be economic to use a plate mill, a hammer mill and a crushing mill to meet the variable requirements of the beef and dairy cattle, poultry and pigs.

WhatsApp: +86 18037808511

Rod Mills — these rotating mills use rods for grinding media causing friction and attrition between steel rods and ore particles. Rod mills can accept feed up to approximately 50 mm. (2 in.) and ...

WhatsApp: +86 18037808511

In the construction of the design it is expected to use indigenous technology and to increase efficiency, minimize cost and maximize profit. The machine was designed to use the main drive shaft as means of speed reduction. It is very cheap to maintain. Download Free PDF View PDF

WhatsApp: +86 18037808511

theoretical efficiency of the double roll crusher when crushing limestone was 60% while that of kaolin was 80%. Keywords: Double roll, crushing, Particle size, design analysis, solid mineral. 1. Introduction Crushing" and "grinding" have been in use since the beginning of human existence.

WhatsApp: +86 18037808511

The first step of physical beneficiation is crushing and grinding the iron ore to its liberation size, the maximum size where individual particles of gangue are separated from the iron minerals. A flow sheet of a typical iron ore crushing and grinding circuit is shown in Figure (based on Ref. [4]).This type of flow sheet is usually followed when the crude ore contains below 30% iron.

WhatsApp: +86 18037808511

The energy consumption of the total grinding plant can be reduced by 2030 % for cement clinker and 3040 % for other raw materials. The overall grinding circuit efficiency and stability are improved. The maintenance cost of the ball mill is reduced as the lifetime of grinding media and partition grates is extended.

WhatsApp: +86 18037808511

The cyanidation plant consists of a primary crushing plant, a semiautogenous grinding circuit, agitation leaching circuit, cyclone wash circuit, gold recovery circuit and carbon regeneration circuit. ... SAG Mill Design and Specification . The Kidston plant was designed to process 7500 tpd fresh ore of average hardness; but to optimise profit ...

WhatsApp: +86 18037808511

Abstract and Figures. It had been reported by the management that BGM grinding circuit was designed to produce final product size of 125 μm, which had not been achieved for a long period of time ...

WhatsApp: +86 18037808511

SAG and ball mill circuit layout and design;.Design of a crushing system that improves the pper mining process plant in stone crusher machine; design crushing mill machine ppt Construction Mobile. design crushing mill machine mill or Raymond grinding mill is a type of stone grinder machine applied as Raymond coal mill. design ...

WhatsApp: +86 18037808511

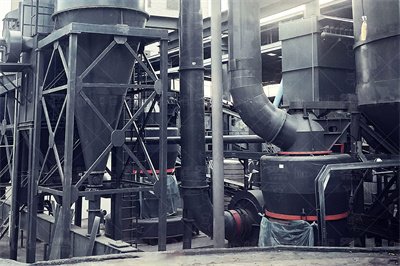

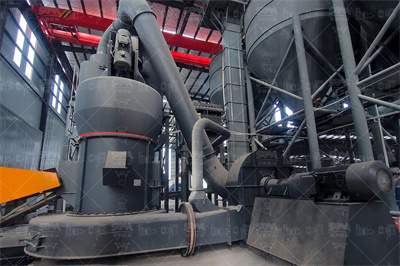

The choice of mill design depends on the particle size distribution in the feed and in the product wanted. Often the grinding is more economic when executed in a primary step, followed by a secondary step, giving a fine size product. As experts in crushing and grinding can offer a full range of grinding mill types and sizes.

WhatsApp: +86 18037808511

ment of grinding media which results in collisions is affected by mill design, mill speed, mill filling and grinding media properties[14]. The collision impact cause particle breakage due to the kinetic and potential energy of the grinding media. For a successful collision to happen, the grinding media should attain a minimum collision energy ...

WhatsApp: +86 18037808511

Contribute to luoruoping/id development by creating an account on GitHub.

WhatsApp: +86 18037808511

Mill design Read online for free. ... 101768RPT0002. Revision Number 0. Calico Resources USA Corp. Grassy Mountain Gold Project, Malheur County, Oregon, USA Mill Design Report June 2019 June 24 2019 Disclaimer This document and its contents were prepared for Calico Resources USA Corp. ("Calico") for the particular purpose which Calico previously described to Ausenco Engineering Canada ...

WhatsApp: +86 18037808511

HPGR crushing may provide a profitable alternative or addition to a grinding circuit allowing the crushed pebbles to be bled to the subsequent downstream ball mill grinding and beneficiation ...

WhatsApp: +86 18037808511

The hammer mill is a power mill making use of a highspeed rotating disc, which is stationary to a number of hammer bars that move superficially by a centrifugal force. The machine was made ...

WhatsApp: +86 18037808511

Given the energy consumption distribution of ore crushing and grinding [Morrell, 2004, 2008, and 2009], the particle size of the crushed final product should be reduced as much as possible in the production process. ... and these programs contain computer simulation models for ball mill design. These models need the input of characteristic ...

WhatsApp: +86 18037808511

An H (m, g, k, 3) design is a triple (X, T, B), where X is a set of mg points, T a partition of X into M disjoint sets of size g, and B a set of kelement transverses of T, such that each 3 ...

WhatsApp: +86 18037808511

Crushing Plant Flowsheet DesignLayout. In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2in. size, but they work much more efficiently if their feed is ½ in. or less. Before the advent of the Symons cone crusher ...

WhatsApp: +86 18037808511

from the mill in order to determine the performance of the mill. The design results show that the minimum shaft power required to drive the ball mill is horsepower, the length of the mill at a fixed mill diameter of 210 mm is 373 mm, and the required shaft length and diameter are mm and 30 mm respectively. The results of the ...

WhatsApp: +86 18037808511

A comminution circuit of threestage crushing and onestage milling was adopted by configuring the tower mill after HPGR. As shown in Fig. 1, the primary crushing involves a C80 Jaw crusher comminuting the ROM ores from − 350 to − 70 mm for feeding the secondary secondary crushing, a GP100M cone crusher is closed with a YA1836 circular vibrating screen to generate − 12 mm ...

WhatsApp: +86 18037808511

There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The paper analyses all of these steps Keywords Gold mining, crushing, Zimbabwe, jaw crusher, cone crusher Introduction

WhatsApp: +86 18037808511

Design and Evaluation of Crushing Hammer mill Mohamed Ibrahim A grain size reduction hammer mill for crushing corn (Zea mays L.) was designed depending on variety characteristics and by using computer aided design "ANSYS" software.

WhatsApp: +86 18037808511