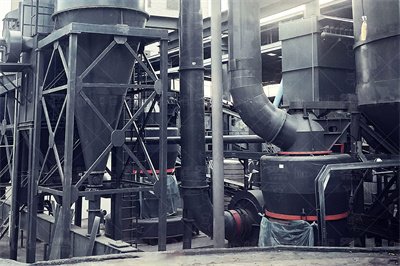

limestone ball mill coal power plant Mining crushing machinery liming Heavy Industry is a professional Quarry Crushing equipment manufacturing company, we produce all types of ore mineral crusher, mill, sand making machine .

WhatsApp: +86 18037808511

Facing an everincreasing demand for power and the obligation to meet strict environmental regulations, power utilities need to make a leap forward. We give you the benefits of our expertise and knowhow to meet and even exceed power utilities industry expectations through design and supply of equipment and systems worldwide. Products. Services.

WhatsApp: +86 18037808511

Ball Mills Thermal Power Plant Limestone. 2022year1month13day · ball mills. the ball mill isumbling mill that uses steel balls as the grinding media. the length of the cylindrical shell is usually times the shell diameter . Chat Online. github.

WhatsApp: +86 18037808511

ball mills thermal power plant limestone. ball mill in power plant. Apr 09, 2021· Normally low speed ball mills or medium speed vertical spindle mills are employed in thermal power plant for this purpose. The milling system is an important part of the auxiliary equipment of a coalfired power plant. Pulveriser mill are one of the critical ...

WhatsApp: +86 18037808511

cost of limestone mill setup plant in rajasthanPulverizer Wikipedia. limestone mill setup plant in rajasthan cost of limestone mill setup plant in limestone flour mill No Comments on limestone ball mill coal power plant limestone A pulverizer or grinder is a mechanical device for the grinding of many different types of materials For example a pulverizer mill is used to pulverize coal for ...

WhatsApp: +86 18037808511

Nowadays, ball mills are used widely in cement plants to grind clinker and gypsum to produce cement. In this work, the energy and exergy analyses of a cement ball mill (CBM) were performed and ...

WhatsApp: +86 18037808511

Besides, the Bond test involves a much more complex procedure and is more laborious than the Hardgrove test. Therefore, for various thermal power plants using coal and limestone, some improvement in mill efficiency and energy cost can be expected if the same grindability test is used for both coal and limestone (Hower et al., 1992).

WhatsApp: +86 18037808511

Power Plant In Use Ball Mills . Ball mill used in coal burning power plant ball type coal mill used in power plant pulverizer crushing coal grinding mill in power plant Jun 10 called a tube mill and due to use of grinding balls for crushing it is called a ball mill power plant coal mills 18 Sep Mills and pulverisers for coal type coal 21 Stone Crusher 21 Jaw Crusher vertical coal mill 3 days ...

WhatsApp: +86 18037808511

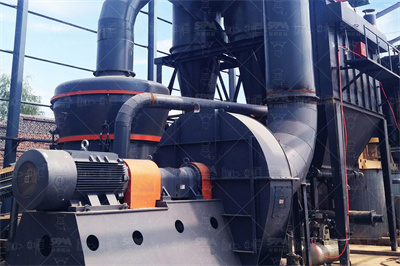

Heavy Power Equipment Plant Ramachandrapuram, Hyderabad 502032 SPECIFICATION No.: BA89015 ... Patratu Thermal Power station (PTPS) is located just outside the coal belt of South Karanpura in Ramgarh ... The Gravimetric feeder feeds limestone to Wet ball mill system. The Wet Ball Mill system consists of Wet Ball Mill, Wet Ball Mill Lubrication ...

WhatsApp: +86 18037808511

Contribute to naicha22/2022 development by creating an account on GitHub.

WhatsApp: +86 18037808511

Contribute to yunan88/crusher development by creating an account on GitHub.

WhatsApp: +86 18037808511

The Ball mill pulveriser is basically horizontal cylindrical tube rotating at low speed on its axis, whose length is slightly more to its diameter. The inside of the Cylinder shell is fitted with heavy cast liners and is filled with cast or forged balls for grinding, to approximately 1/3 of the diameter.

WhatsApp: +86 18037808511

The mill slurry pump will send limestone to ball mill classifier to classify big size limestone. Then, the overflow of the ball mill classifier shall go to the central slurry tank. The agitator is provided to keep the slurry solids in suspension during tank usage. 3. Limestone Slurry Storage Tank

WhatsApp: +86 18037808511

Contribute to brblmd/sbm development by creating an account on GitHub.

WhatsApp: +86 18037808511

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('') and can be up to 35 characters long.

WhatsApp: +86 18037808511

1 Outsorced limestone powder for FGD; 2 Selfbuilt dry limestone mills outside the coalfired power plants; 3 Selfbuilt wet limestone mills inside the coalfired power plants. For decades, we have been optimizing limestone mills to meet specific customer needs.

WhatsApp: +86 18037808511

Contribute to sili2023/sbm development by creating an account on GitHub.

WhatsApp: +86 18037808511

sbm/sbm ball mill for thermal power rwrr KiB . View; Log; Blame; View raw; Permalink; 40cddf99 — mill2022 sbm 4 months ago

WhatsApp: +86 18037808511

Equipment for engineering education . Thermodynamics, Heating and Sanitary Systems. Fluid Mechanics and Hydrology. Process Control and Process Engineering > . CE 245 Ball Mill: Print.

WhatsApp: +86 18037808511

Ball Mill Plant high efficiency, low energy consumption Ball mill machine is the key grinding equipment for grinding materials after crushing It mainly consi. ... ball mill for power plant T05:03:56+00:00 Who we are > Products > Cases > Solutions > Contact Us >

WhatsApp: +86 18037808511

The Emax is an entirely new type of ball mill for high energy milling. The unique combination of high friction and impact results in extremely fine particles within a very short process time. The high energy input is a result of the extreme speed of 2000 min1 and the optimized jar design. Thanks to the revolutionary cooling system with water ...

WhatsApp: +86 18037808511

You cannot select more than 25 topics Topics must start with a letter or number, can include dashes ('') and can be up to 35 characters long.

WhatsApp: +86 18037808511

Coal Mills in Thermal Power Plant Mill Grinding . mill reject system 7 operational parameters 8 maintenance practices 9 comparision of tube ball mill it is the most easily and abundantly available cheap and transportable energy source types of coal based on proximate analysis of coal on dry basis 1 anthracite 2 bituminous 3 b bituminous 4 lignite pulverised form of coal

WhatsApp: +86 18037808511

BALL MILL FEEDER SELECTION DATA LIMESTONE ANALYSIS/CHARACTERISTICS The following limestone property to be used designing Limestone grinding system WATER ANALYSIS The following water to be used during the grinding process of limestone in Lime stone grinding system (LGS)

WhatsApp: +86 18037808511

By stirred ball grinding of 20 min, the median particle size of the limestone products was μm. The specific energy value was determined from the stirred ball mill power of 178 Nm/s by filling ratio of 70% (the solid mass concentration was 20%). Table 5 presents the mill power and the specific grinding work for the wet grinding process ...

WhatsApp: +86 18037808511

This has the following advantages Higher mill output Less wear Lower power consumption (up to 5% reduction is expected) Lesser maintenance Hence, all the new plants installing ball mills, should prefer high efficiency mill internals. Target power consumption of (VRM) 18 units/ton of cement for medium hard limestone (or) 1112 units/ton of ...

WhatsApp: +86 18037808511

Crushed ore is fed to the ball mill through the inlet; a scoop (small screw conveyor) ensures the feed is constant. For both wet and dry ball mills, the ball mill is charged to approximately 33% with balls (range 3045%). Pulp (crushed ore and water) fills another 15% of the drum's volume so that the total volume of the drum is 50% charged.

WhatsApp: +86 18037808511

Jun 26, 2019 ball mills thermal power plant limestone, Thermal power station Wikipedia 2018 7 6 The direct cost of electric energy produced by a thermal power station is the result of cost of fuel, capital cost for the plant, operator labour, maintenance, and such factors as ash handling and disposal.

WhatsApp: +86 18037808511