Low investment. The steel structure of the vertical kiln has fewer machined parts so its processing cost is low and the installation difficulty is not high. Shaft kiln is also called vertical shaft kiln which is one of the cement kilns widely used in the cement production line. As the main cement equipment, it plays an important role in cement ...

WhatsApp: +86 18037808511

Once the raw materials have been crushed into raw meal, they are transported to the kiln and Howden fans play an important role in super heating the meal into the cement clinker and then to cool the clinker. The clinker then has gypsum added and is moved into the cement mill to be ground into the final product. ... (Dunbar cement plant, UK ...

WhatsApp: +86 18037808511

demonstration installation at a cement plant in the Midwestern (Figure 3). The Midwest installation in KY/IL area was an older, long, dry, horizontal kiln without an inline raw mill. ... an inline kiln/raw mill has a significant effect on the speciation of mercury. Souteast Cement Plant with inline mill 0 50 100 150 200 250 ...

WhatsApp: +86 18037808511

Analysis of energy balance was used to determine the sources of heat loss from kiln system. The major heat loss is Heat losses by the kiln exhaust gas (%) Hot air from cooler stack (% ...

WhatsApp: +86 18037808511

Why choose us. VSK cement plant is short of vertical shaft kiln cement plant, it is mainly applied for small scale cement plants. As the name suggested, the core equipment of the cement plant is vertical shaft kiln. To meet various needs of clients, we supply different sizes of VSK cement plants, such as 50 TPD, 65 TPD, 75 TPD, 100 TPD, 150 TPD ...

WhatsApp: +86 18037808511

A new initiative was taken up last year by LT, for the first time in the country: a 25 tonne tower crane was used in the construction of cement plants. It was strategically placed near the preheater tower and the raw mill for structural and equipment erection. This has reduced the overall cycle time of erection activities.

WhatsApp: +86 18037808511

Kiln Raw Mill System. Cement Manufacturing Technology. 14. Kiln Raw Mill System. We have now reached the heart of the cement manufacturing process, the combined kiln and raw mill system. We have discussed raw mills and kiln feed homogenisation silos, but these equipment items cannot be considered in isolation.

WhatsApp: +86 18037808511

cement Scribd, Raw mill; Kiln and preheater; ... 33 Kiln and preheater ... This system applies for the first time in the cement plant a concept of separating the ... Go to Product Center. cement kiln tire grinding machine Grinding Mill China, Rotary Kiln Cement Plant. ... raw mill and rotary Kiln energy and mass balance ...

WhatsApp: +86 18037808511

National Cement of Alabama commissioned the new kiln line in a ceeremony on July 21, 2022. National Cement Company of Alabama's longtime Ragland manufacturing plant is just concluding a twoyear, 300million project to install cement production equipment designed to take advantage of the very latest carbon reduction practices and modern energy ...

WhatsApp: +86 18037808511

specified in §(b)(7) while the raw mill of the inline kiln/raw mill is operating and while the raw mill of the inline kiln/raw mill is not operating. (iv) The time weighted average total organic HAP concentration measured during the separate initial performance test specified by §(b)(7) must be used to determine initial compliance.

WhatsApp: +86 18037808511

The SP exhaust gas is used within the cement plant for drying raw materials. The WHR generation system design must consider the drying requirements in the cement plant raw mill to optimize the amount of electricity generated on an annual basis [125]. 6. Conclusions Following conclusions can be drawn from this study: 1.

WhatsApp: +86 18037808511

The cement kiln used in wet production is called wet kiln, and wet production is to make raw material into a slurry with a moisture content of 32% to 40%.

WhatsApp: +86 18037808511

Simplified clinker diagram using raw materials and alternative fuels. 1. fan branch A; 2. fan branch B; 3. heat exchanger (preheater) for raw materials in the form of flour; 4. rotary kiln for ...

WhatsApp: +86 18037808511

AGICO is a cement equipment supplier with more than 30 years of production and sales experience. We provide customers with all kinds of cement equipment as well as the entire cement production line. Cement rotary kiln is our hotsale product, the output can reach t/d and the size is between φ*39m to φ*74m.

WhatsApp: +86 18037808511

sbm / sbm kiln and raw mill dedus.... 19 KiB Raw Permalink Blame History Unescape Escape Permalink Blame History Unescape Escape

WhatsApp: +86 18037808511

The cement production source category consists of each kiln and each inline kiln/raw mill at any portland cement manufacturing facility, including alkali bypasses and kilns and inline kilns/raw mills that burn hazardous waste. What Greenhouse Gases Must Be Reported? Cement production facilities must report the following emissions:

WhatsApp: +86 18037808511

The rotary kiln is the heart of a cement manufacturing plant. Cement kilns have all chemical ingredients. These ... (GCT) followed by Electrostatic Precipitator (ESP) for the control of particulate emissions from the kiln and raw mill. Since the existing circuit was designed in early 90's for lower capacity of Kiln, CCCL wanted to look at the ...

WhatsApp: +86 18037808511

For kiln 7, clay was prepared by an oilfired (later coalfired) crusher/drier. The raw mill, as installed, was a 2250 kW ball mill, heated by kiln exhaust. Later replaced by vertical mill? For kiln 8, Polysius RM46/23/85 roller mill, table dia. m (1) Eight rotary kilns were installed: Kiln A1. Supplier: FLS Operated: Mid August 1929 1986 ...

WhatsApp: +86 18037808511

Improve the thermal load of the rotary kiln: It has been found through research and practice that increasing the coal consumption of the rotary kiln head can potentially exploit the production capacity of the rotary kiln, thereby increasing the output of the entire cement production, and calcining the clinker under specific raw materials.

WhatsApp: +86 18037808511

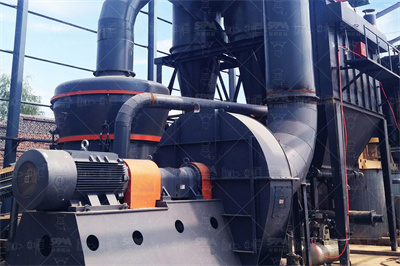

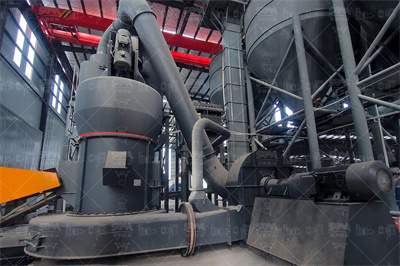

Raw Mill Fans Fans with high pressure, abrasive and sticky dust are normally used for raw mill applications. Hard facing liners are foreseen on impeller blades and centre plate; material of chromium carbide used against dust abrasion.

WhatsApp: +86 18037808511

Cement Plant mainly composed by crushing equipment,homogenize equipment,raw material preparation equipment,drying equipment,preheat and predecomposition equipment,the clinker sintering equipment,cooling equipment,grinding equipment,packaging equipment,conveying equipment,environmental production dust collection equipment Winnermac supply process design,civil construction,complete ...

WhatsApp: +86 18037808511

Cement Plant Operation Handbook Free ebook download as PDF File (.pdf), Text File (.txt) or read book online for free. ... 1 Kiln Specific Fuel Consumption: 2 Cement Mill Specific Power Consumption: 3 Other Systems: ... drying can be performed in the raw mill from up to 15% aggregate moisture but predrying may be necessary for certain ...

WhatsApp: +86 18037808511

AGICO is an experienced cement equipment manufacturer in China. In cement plant construction, the cement rotary kiln and vertical shaft kiln is the main cement kiln we adopt. They are very different in calcination methods and properties. Next, we will look at these two cement kilns in detail. What Is Cement Rotary Kiln?

WhatsApp: +86 18037808511

The cement rotary kiln is a cylindrical body with a certain inclination, and the inclination is 3 to %. The rotation of the kiln is used to promote the stirring of the material in the rotary kiln, and the materials are mixed and contacted for reaction. The combustion of the kiln head fuel produces a large amount of heat, and the heat is ...

WhatsApp: +86 18037808511

Cement kiln is used to calcine cement clinker in the cement plant, also known as cement plant kiln. Like we all know, cement production line include three main steps: preparation of cement raw materials, clinker production, and finished cement production. As a core cement equipment of clinker production, cement kiln is applicable for various ...

WhatsApp: +86 18037808511

Published Dec 19, 2022 + Follow A raw mill is a type of grinding machine used to crush material into a fine powder. It is an essential component in cement plants because it is used to grind...

WhatsApp: +86 18037808511

Hotsale Cement Equipment. AGICO is a leading cement equipment manufacturer in China, supporting highquality cement kilns, cement mills, cement crushers, industrial dust collectors, conveying equipment, and other machines that are needed in the cement plant. We offer customization, installation, commissioning, and operation training services.

WhatsApp: +86 18037808511

Introduction of the cement kiln in this study. In this study, experiments were carried out on a 4000 t/d new suspension (NSP) production line with a fivestage preheater at a plant of Huaxin Cement Co., Ltd. Domestic waste, municipal sludge, general solid waste, and other wastes were used as alternative fuels and raw materials (AFR) in this kiln.

WhatsApp: +86 18037808511

The data are referred from a cement plant and modeling is done with related calculations and SEIDER TATE analysis using MATLAB code 45 tool. In a cement rotary kiln, high temperature heat is directly dissipated into atmosphere by means of exhaust flue gases and radiation energy through hot kiln shell surface.

WhatsApp: +86 18037808511

To keep air conditions clean and cool, Robinson Fans' experienced and knowledgeable technical team can recommend solutions that meet the specifications of any cement plant installation. 136inch diameter, 4000 Horsepower, 470,000 ACFM raw mill fan for a cement producer in Michigan.

WhatsApp: +86 18037808511

study Union Bridge cement plant kiln feed is presented in Table 3. The ... The raw mill and kiln dependent quality tar gets . noted in Section 3 of this manuscript is used as a c utoff for the 3D .

WhatsApp: +86 18037808511