The earliest known record of one comes from the ancient Roman Republic in the palace of Mithradates VI Eupator, ruler of Pontus. This early form was a cogandaxis water mill predominantly used to crush corn. Running water made mills more powerful and allowed people to crush hard materials with less effort.

WhatsApp: +86 18037808511

October 1955 Volume 6 Issue 6 While the antiquarian still coos over many a useless relic of the past, the American miller and his mill have often been forgotten. Like the farmer and the barn builder, his name is seldom recorded; but his place in the fabric of our history is distinct.

WhatsApp: +86 18037808511

A few years ago, when I visited Saugus, a History Channel TV crew was doing a video of the tilt hammer operating, along with the rest of the site. Maybe it is on Youtube or something. I believe almost all of the 1646 Saugus iron works is 20th century reconstruction. But the museum did have an old hammer head on display.

WhatsApp: +86 18037808511

The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and particularly the Edison roll crusher and in these machines ...

WhatsApp: +86 18037808511

Rock Crusher History. History tells us, it was in 1830, the first US patent was issued on a rock crushing machine. It covered a device which, in a crude way, incorporated the drop hammer principle later used in the famous stamp mill, whose history is so intimately linked with that of the golden age of mining. In 1840, another patent was issued ...

WhatsApp: +86 18037808511

10 HP To 100 HP Stainless Steel Hammer Mill Machine, Capacity: 50 kg/Hr To 3000 kg/Hr. ₹ 90,000 Get Latest Price. Power: 10 HP to 100 HP. Capacity: 50 kg/hr to 3000 kg/hr. Material: Stainless Steel. Brand: Grade Grind. Country of Origin: Made in India. Voltage: 440 V.

WhatsApp: +86 18037808511

The working principle of the hammer mill is simple to understand. The principle is illustrated in Fig. 1 (a). It only requires choosing an appropriate motor, crushing hammers/knives and material to be crushed. It operates on the principle of impact between rapidly moving hammers mounted on the rotor and the stationary powder bed.

WhatsApp: +86 18037808511

Hammer mill Impact mills are similar in construction and principal to HSI and VSI crushers. Impact mills are used to pulverize feed material by impact against a surface or a bed of feed material. The feed material may be propelled by gravity or by a rotating impeller or rotor. The impellers or rotors can be vertically or horizontally orientated.

WhatsApp: +86 18037808511

Although there is no hard evidence that the waterpowered paper mills that are noted in twelfthcentury Spain were of Islamic origin, there is no reason to believe that they were not (Hill, 1993, p. 113). This varied evidence suggests, therefore, that waterpowered hammer mills spread around the Mediterranean along with Islam and the ...

WhatsApp: +86 18037808511

Origin Country Port of Discharge Unit Quantity Value (INR) Per Unit (INR) Jul 26 2016: : SUPPORTING ARM CPL. FOR HAMMER MILL AWSK 630 NV (1 SET = 6PCS) Germany: Kolkata Air Cargo: PCS: 6: 226,576: 37,763: Jul 26 2016: : HAMMER MILL SCREEN + = INCLUDING SCREEN FRAME FOR HAMMER MILL AWSK 630NV (1 SET = 6 PCS ) Germany ...

WhatsApp: +86 18037808511

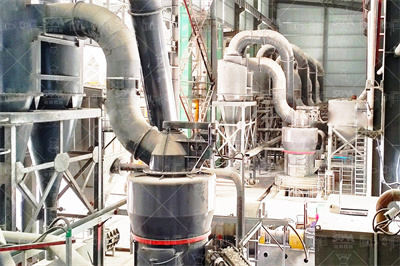

A hammer mill is a mill whose purpose is to shred or crush aggregate material into smaller pieces by the repeated blows of little hammers. These machines hav...

WhatsApp: +86 18037808511

What is a Hammer Mill? A hammer mill is a machine that uses a crushing technique to grinding solid food products that need to be broken down into suitable forms. They are highly effective at grinding the solids without making too much noise, and as for pharmaceutical processes, there's also minimal heat buildup.

WhatsApp: +86 18037808511

While these machines may have evolved from their humble beginnings into highly efficient tools, their clunkier ancestors from the turn of the century can still put in a hard day's work, whether that's by working on the farm or getting toured around your local area. How Hammer Mills Work

WhatsApp: +86 18037808511

Applications of Hammer Mill. Nonabrasive to moderately abrasive materials are size reduced. Cakes, slurries ointments filter press cakes can also be milled. Modifications of Hammer Mill. Fitz mill/Fitz Patrick Comminuting machine It is used for size reduction of the materials like herbs, glands, livers, roots etc. Stoke Tornado Mill.

WhatsApp: +86 18037808511

A] Hammer Mill Working Principle and Main Components. The process of size reduction (for feed material) is carried out by rectangular pieces of hardened steel that rotate inside the chamber at a high speed, striking the material to be milled with a powerful force. These radially swinging hammers (from the turning central shaft) help crush/grind ...

WhatsApp: +86 18037808511

Hammer configuration and thickness: more hammers means finer grinding, but also higher energy requirements. Thin flat hammers (3 mm.) generally affect milling positively in terms of output and thicker hammers tend to push the product forward, instead of reducing it. The degree of wear should be checked regularly: excessively worn hammers reduce ...

WhatsApp: +86 18037808511

Hammer mills are often used for generalpurpose grinding and the finished product particle size ranges from millimeters to tens of microns. The jet mill is primarily used for superfine grinding applications and creates particles sizes down to a few microns. Understanding the fundamentals of each mill's respective grinding mechanisms ...

WhatsApp: +86 18037808511

a stronghold. a complete extent or range. TAKE THE QUIZ TO FIND OUT Origin of hammer mill 1 First recorded in 160010 Words Nearby hammer mill hammered Hammerfest hammerhead hammerless hammerlock hammer mill hammer out hammer pond hammer price Hammersmith Hammersmith and Fulham

WhatsApp: +86 18037808511

Who we are Hammermill® is the leading millbrand paper in North America. Since 1898, we've made it easy to choose Paper Made Right®. Not all paper is the same. When you want sustainablyproduced, Americanmade quality — so you can feel as good about your paper as you do about what's printed on it — choose Hammermill. Philanthropy

WhatsApp: +86 18037808511

A sugarloaf was the traditional shape of sugar in the eighteenth century: a semihard sugar cone, usually with a rounded top, that required a sugar axe or hammer to break up and sugar nips to reduce to usable pieces. Sugar Prices . The history of sugar has five main phases: . The extraction of sugar cane juice from the sugarcane plant, and the subsequent domestication of the plant ...

WhatsApp: +86 18037808511

Grist mills constructed in the early 1600's to grind corn and wheat to make flour for the early English settlers of coastal areas. Two words in this sentience reveal was the mill was constructed to do. These words are: corn and flour. To English speaking people of the 1600's and 1700's a corn mill means a mill that grinds corn and makes flour.

WhatsApp: +86 18037808511

A hammer mill. In the background is the bloomery (Rennofen), in front of it a bloom is being coarsely freed of the near foreground, the bloom is being forged under the hammer.. A hammer mill, hammer forge or hammer works was a workshop in the preindustrial era that was typically used to manufacture semifinished, wrought iron products or, sometimes, finished agricultural or mining ...

WhatsApp: +86 18037808511

Hot metal ingot being loaded into a hammer forge A billet in an opendie forging press. Forging is a manufacturing process involving the shaping of metal using localized compressive forces. The blows are delivered with a hammer (often a power hammer) or a is often classified according to the temperature at which it is performed: cold forging (a type of cold working), warm forging ...

WhatsApp: +86 18037808511

Multimill hammer mill series. The Multimill series consists of finegrinding hammer mills. The Multimill is designed with small hammertoscreen clearance that secures minimum particle size. Key features: Optimum particle reduction; Small screen area; Low temperature operation for protection of nutritional value of feed ingredients

WhatsApp: +86 18037808511

The history of the hammermill dates back over 1,500 years to the 5 th century. Unlike the hammermills used today, these machines were most often used to create weapons or for mining. In 488 AD, the Chinese inventor and engineer Zu Chongzhi invented a waterpowered hammermill.

WhatsApp: +86 18037808511

A mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand or by animals (, via a hand crank), working ...

WhatsApp: +86 18037808511

VIEWS Hammer mill is the most widely used grinding mill and among the oldest. Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case. It produces size reduction by impact.

WhatsApp: +86 18037808511

History Arm and Hammer trade card from the 1870s, showing the logo Name and logo. The original Arm Hammer logo usage dates back to the 1860s. James A. Church, son of Dr. Austin Church, ran a spice business known as Vulcan Spice to the company, the Arm and Hammer logo represents Vulcan, the Roman god of fire and metalworking.. It is often claimed that the brand name originated ...

WhatsApp: +86 18037808511

Working of Hammer Mill. The hammer mill works by introducing the material to be ground into the feed hopper. The material is then pulled into the mill by the rotation of the rotor. As the rotor spins, the hammers strike the particles, breaking them down into smaller pieces. The ground material is then discharged through the discharge chute.

WhatsApp: +86 18037808511

View of the plant's hammer shop and its furnaces, 1922. Control house for the mills, 1922. Laboratory building, 1922 ... The facility served as a refinery and rolling mill for the nickel and nickelbased alloys melted at the Orford Works in Bayonne, New Jersey. ... James E. Floodwall History, Huntington Quarterly. September 27th 2018. Accessed ...

WhatsApp: +86 18037808511

Hammer mills are common equipment for this stage of mechanical preprocessing. Hammer mills use large rotating drums with protruding metal bars (, hammers) that impact the material at high velocity to shatter and tear material particles. Typically, the metal bars swing freely from the drum, but fixed hammers are also common in hammer mill ...

WhatsApp: +86 18037808511