Input coal size is 25 mm while output is 6575 micron. Crushing of coal by replaceable bull ring segment and grinding rolls. Externally adjustable classifier for segregation of fine coal practices. Removable planetary gearbox External journal design Horizontal pivot scrapers Aerodynamic vane wheel Extended life of all wearing parts

WhatsApp: +86 18037808511

Pulveriser ring mill 1000; Lab disk pulverizer; Pulveriser ring mill lm2000 soil samples ... soil samples; Mild steel disc grinder pulverizer 12 inch, 5 hp; Disc pulverizer; Disc grinder (vertical type), model name/number: dksc; Mild steel lab pulveriser manufacturer, capacity: 50 kg; Mild steel laboratory coal pulverizer machine manufacturer ...

WhatsApp: +86 18037808511

Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size. Rotary kilns then use the powders as fuel burners. The VCM has a housing section equipped with a lining ...

WhatsApp: +86 18037808511

Introduction. This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes.. The 3D model in the saVRee database represents a vertical grinding bowl grinding mill types include the ball tube mill, hammer mill, ball and race mill, and, roll and ring mill.

WhatsApp: +86 18037808511

We're a world leader in coal pulverizing and boiler mill operations for horizontal and vertical boiler mills—committed to highefficiency performance, reduced maintenance costs, and longer time between outages. Can GE service my boiler mills? YES.

WhatsApp: +86 18037808511

Erie, PA | . Request For Quote. Eriez designs and manufactures pulverizers as well as a wide variety of other size reduction equipment. Our pulverizers can crush coal, chemicals, spices, bricks, soil, and more. We have developed solutions for the food, chemical, mining, and many other industries.

WhatsApp: +86 18037808511

equipment manufacturers' pulverizers sized for about 120,000 pounds of coal pulverization per hour: one an RP mill design (Figure 1) and the other an MPS design (Figure 2). Both mills have vertical spindles and horizontal grinding tables or bowls. In part one of this series, pulverizer capacity or

WhatsApp: +86 18037808511

Bowl Mills Capabilities. Bowl mills supplied by Wabash Power are capable of grinding harder coal with higher percentage moisture content and can reduce the product fineness in excess of 90% passing a 200 mesh screen at a reduced output capacity. The feed size of the coal to the mill should be precrushed to 1" top size.

WhatsApp: +86 18037808511

Today, with more than 1,100 BW Roll Wheel pulverizers sold worldwide and six different sizes burning a variety of coals, BW has the proven design and operating experience to meet your specific project requirements. This performance has made the BW Roll Wheel pulverizer the pulverizer of choice for coalfired boiler operators and owners.

WhatsApp: +86 18037808511

• Coal Rejects Less then 10 #'s per hour. • Pulverizer Power With fuel changes to low HGI coals or operations with lower BTU coal (exceeding design capacity), mill motors are often undersized to achieve desirable performance. • Fuel Line Temperature of 165 175°F with low volatile coal (may require synthetic

WhatsApp: +86 18037808511

Williams Vertical Roller Mill Pulverizers are perfect for coal and pet coke applications requiring fine to ultrafine particle sizes for direct firing into boilers and kilns. This type of coal pulverizer uses centrifugal force to grind solid fuels while maintaining low operating costs.

WhatsApp: +86 18037808511

Coal pulverizer plant for UK,coal ball mill,coal vertical . Coal grinding is an effective technique to improve burning efficiency and maximize energy output. Pulverized coal processing and storage systems are generally .

WhatsApp: +86 18037808511

Nowadays, Loesche vertical mills form the core of many plants used to drygrind coal, cement raw materials, granulated slag, industrial minerals and ores. Thanks to its grinding plants with throughputs of 2 to 1000 t/h for the cement industry and selfinert, central coalgrinding plants for hard and brown coal power stations, Loesche is the ...

WhatsApp: +86 18037808511

Fineness is an indicator of the quality of the pulverizer action. Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50, 100, and 200 mesh A 70% coal sample passing through a 200 mesh screen indicates optimum mill performance. The mill wear and the power consumption are increased if the 70% ...

WhatsApp: +86 18037808511

Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size. Rotary kilns then use the powders as fuel burners. The VCM has a housing section equipped with a lining ...

WhatsApp: +86 18037808511

The Raymond® Bowl Mill is considered the finest vertical roller mill available for pulverizing coal. The typical Raymond bowl mill system is designed to simultaneously dry, pulverize, and classify solid fuels to 95% passing 200 mesh (<5%R75μ) with a wide range of capacities from 24 to 150 stph.

WhatsApp: +86 18037808511

Let's take two different original equipment manufacturers' pulverizers sized for about 120,000 pounds of coal pulverization per hour: one an RP mill design (Figure 1) and the other an MPS ...

WhatsApp: +86 18037808511

for Coal Pulverizer Systems Technical Publication 5 NEPONSET STREET, WORCESTER, MA ... Typical implementations of centrifugal classifiers are shown in Figure 1 in a vertical pulverizer and a ball tube mill with external classifier. (a) (b) Figure 1. (a) Vertical Mill with Centrifugal Classifier and (b) Stand ...

WhatsApp: +86 18037808511

As an Original Equipment Manufacturer of three distinctly different coal pulverizer systems, Riley Power Inc. understands the necessity of optimizing pulverizer system operation. The Riley Power family of pulverizer offerings includes the MPS vertical roller mill, the Atrita highspeed attrition mill and the ball tube mill. PULVERIZER SERVICES

WhatsApp: +86 18037808511

Pulverizer Liming Heavy Industry. Pulverizer Series; Product List; Service; Contact Us; Contacts. Tel: Fax: E_mail: .. › European Type Jaw Crusher › Jaw Crusher.

WhatsApp: +86 18037808511

Large coal pulverizers have been identified by EEI surveys as one of the main systems responsible for lost steam generation capacity of large coal fired utility boilers. This report contains the results of a 16 month study to examine the problem of pulverizer outages and to identify root cause failure modes for the major mill types currently in ...

WhatsApp: +86 18037808511

In the pulverizers segment, MAAG offers a wide range of pulverizers for different throughput ranges and applications. Our stateoftheart product portfolio is based on 30 years of research, development, ongoing system improvement, and indepth knowhow in the grinding of plastics and other materials. The range of pulverizers extends from units for small throughputs such as for laboratory or ...

WhatsApp: +86 18037808511

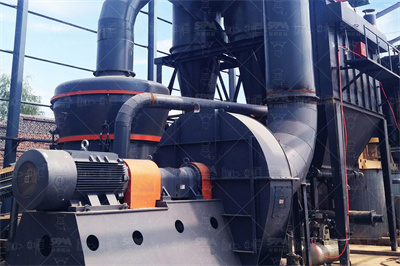

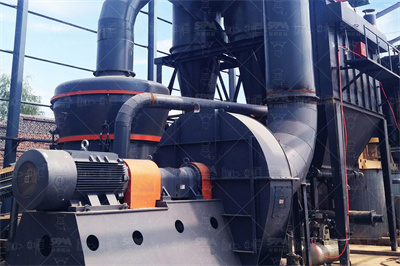

High Light: Vertical Roller slag coal milling machine, Pulverizer slag coal milling machine, Vertical slag coal pulverizer machine High Capacity Vertical Mill Prices / Vertical Roller Grinding Mill Coal Pulverizing Production Line Product Introduction HVM vertical mills are also commonly called roller mills, mediumspeed mills, etc. in ...

WhatsApp: +86 18037808511

Figure 4 is for short vertical runs of coal piping. ... MPS89 Pulverizer with Eight Coal Pipes. ... The next step in this plant is to upgrade the mill to improve coal fineness to 75% passing a ...

WhatsApp: +86 18037808511

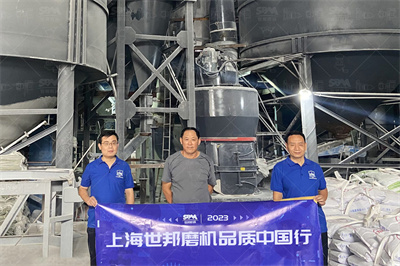

China Vertical Pulverizer manufacturers Select 2023 high quality Vertical Pulverizer products in best price from certified Chinese Milling Machine, Grinding Machine suppliers, wholesalers and factory on ... High Pressure Carbon Vertical Roller Grinding Mill Black Graphite Black Graphite Coal Black Stone Raymond Mill ...

WhatsApp: +86 18037808511

PVPro Recognized Expertise For nearly 100 years—ever since pulverized coal combustion was adapted for power generation—GE has been a leader in coal mill technology for the power industry. That leadership continues today with the world's largest fleet of installed power milling equipment.

WhatsApp: +86 18037808511

Coal Mining Machine Stone Pulverizer Grinding Mill for Barite Fluorite Mica Dolomite Pyrophyllite Mineral Powder Factory. US / Set. 1 Set (MOQ) Type : Micro Powder Grinding Mill. Motor Type : AC Motor. Motor Power : 30KW. Rotationl Speed : 2123r/min. More. Shanghai Clirik Machinery Co., Ltd.

WhatsApp: +86 18037808511

LM vertical coal mill, also known as mediumspeed coal mill, realizes the domestic largescale highend vertical coal mill. LM vertical coal mill system can be drying and grinding at the same time, can realize drying while grinding. Chat Online WhatsApp. Previous Next. Processed Materials: Anthracite. Lignite.

WhatsApp: +86 18037808511

The net effects of leakage flows from, and seal airflow into, mills and pulverizers can be significant (see the "Total coal pipe flowsseal air on" column of Table 1).

WhatsApp: +86 18037808511

Vertical Coal Mill. Feeding size: ≤110mm. Capacity: 570t/h. Motor power: kW. Applications: Vertical coal mill is mainly used for grinding raw coal, bituminous coal, and other fuels into coal powder, which is supplied to rotary kiln and other kilns in the cement plant and thermal power plant. Email: info

WhatsApp: +86 18037808511

China Coal Pulverizer manufacturers Select 2023 high quality Coal Pulverizer products in best price from certified Chinese Coal Mining Equipment, Milling Machine suppliers, wholesalers and factory on ... Flyash Slag Calcium Carbonate Cement Coal Vertical Roller Mill Fine Powder Grinding Mill for Sale . US / Set ...

WhatsApp: +86 18037808511