Purpose Vibration is a major issue in turbomachines which causes damage to them and leads to reduction in life and efficiency. This paper reviews various methods to measure the amount of vibration in various turbomachines and also discusses various reasons for the same. This will significantly assist in articulating these vibrations. Procedure This paper lists various experiments done, causes ...

WhatsApp: +86 18037808511

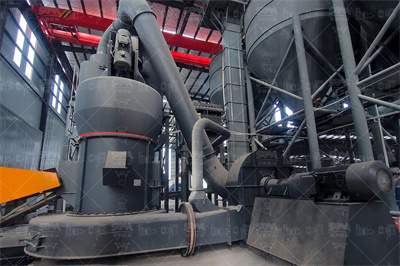

Working Principle Vibration ball mill consists of shelf, underframe, vibration generator, spring, cylinder, motor and so on. When the machine starts up, the motor drives the vibration generator to make continuous vibration, which makes cylinder doing small amplitude and continuous movement with high frequency. Because of self rotation and ...

WhatsApp: +86 18037808511

RETSCH's Vibratory Disc Mill RS 300 is suitable for rapid, lossfree and reproducible grinding of mediumhard, brittle and fibrous materials. Thanks to the robust universal drive shaft, which sets the grinding jar into a 3D motion, the RS 300 accepts grinding set weights of up to 30 kg. The closed grinding system guarantees complete ...

WhatsApp: +86 18037808511

Vibrationassisted machining (VAM) is an external energy assisted machining method to improve the material removal process by superimposing high frequency and small amplitude vibration onto tool or workpiece motion.

WhatsApp: +86 18037808511![Top 10 Vibrating Screen Types Working Principle [How To Choose]](/rlk7nu0/95.jpg)

Highfrequency vibrating screen is usually operated at an inclined angle 0°25°, up to 45°, and the operating frequency range is r/m. 7. Grizzly Screen. Grizzly screen is often used for prescreening before coarse and medium crushing of materials. The mesh size is generally >50mm, but sometimes <25mm.

WhatsApp: +86 18037808511

The vibration analysis above is based on the cutting force excited vibration in milling under nonchatter condition. Furthermore, the machine tool vibration in the system should also be considered; thus, Eq. can be extended to the study of milling vibration with the mechanical vibration superposition principle.

WhatsApp: +86 18037808511

The working principle of the hammer mill is simple to understand. The principle is illustrated in Fig. 1 (a). It only requires choosing an appropriate motor, crushing hammers/knives and material to be crushed. It operates on the principle of impact between rapidly moving hammers mounted on the rotor and the stationary powder bed.

WhatsApp: +86 18037808511

Here are the steps of how to use the hermetic principle of vibration: Step 1: Understand that the only constant is change. Step 2: Change yourself from low vibration to high vibration. Step 3: Keep yourself at the higher vibration for a long period of time.

WhatsApp: +86 18037808511

The grinding mill falls in with popular demands. vibration ball mill Working principle: The high efficiency vibration ball mill is mainly composed of the base frame, the body frame, the acoustic enclosure, the body, the grinding cylinder, the vibrator, the lining plate, the spring support, the grinding medium and the driving motor.

WhatsApp: +86 18037808511

Large production mills operate at relatively low vibrational frequencies and high amplitude (for example, 1000 to 1500 rpm and up to 12 mm, or in.). The vibratory ball mill is an excellent means of producing solidstate alloyed and dispersionstrengthened metals in amounts up to kg (10 lb) or more, depending on the apparent density of ...

WhatsApp: +86 18037808511

1. Introduction. Rolling mills are the main sheetforming equipment in the world. A variety of nonlinear vibration behaviors occur in rolls during production, such as vertical vibration, torsional vibration, bending vibration, and various forms of coupling vibration [1], [2], [3], [4].The causes of these vibration behaviors fall into three main categories, one of which is defects in mill ...

WhatsApp: +86 18037808511

The paper presents a new design of the vibration mill with polyharmonic vibrations, which has three vibratory drives mounted on the grinding chamber with the possibility of varying the frequency ...

WhatsApp: +86 18037808511

Fluid energy mills. The general principle of operation in a fluid energy mill is that the material to be ground is fed into a grinding chamber in a high speed, high pressure and, often, high temperature jet of air (or other gas). The particles collide violently and this causes comminution to take place.

WhatsApp: +86 18037808511

A ball mill, which is used to finely grind materials, causes high levels of vibration and sound during grinding operations. The vibration and sound of mills provide significant information about the internal conditions and can be used to estimate the status of the ground material. We developed a simulation model for the vibration of a mill wall ...

WhatsApp: +86 18037808511

Stateoftheart on the principle and structural design of VAM systems are reviewed. The benefits and applications of VAMilling are discussed with emphasis on machining of hardtomachine materials.

WhatsApp: +86 18037808511

Vibration ball mill, also known as a vibrating ball mill or vibratory ball mill, is a kind of ball mill machine that uses the highfrequency vibration of the cylinder to make the grinding medium in the cylinder impact the material by inertial force. Vibration ball mill is a new type of highefficiency and energysaving grinding equipment.

WhatsApp: +86 18037808511

Sieve Shaker Principle Die sieve shakers work on the principle of vibration, agitation, or gyration. In order to effectively use sieve shakers for screening, data on particle size distribution, sieve load, sieve shaking method, particle shape and size, and ratio of sieve open area to total area must be considered.

WhatsApp: +86 18037808511

Industrial hammer mills are employed in particle reduction applications for processing material. Though machine designs vary, the basic hammer mill working principle remains the same—uniform size reduction of aggregate raw material is achieved by repeated blows with hammers mounted to a rotating shaft. Whether coffee beans or titanium, hammer ...

WhatsApp: +86 18037808511

The principle used is the same as that for active vibration control. The system generates a noise of equivalent frequency content and volume, but in antiphase to the noise to be cancelled. Thus to cancel the noise of a funnel exhaust a loudspeaker producing a carefully controlled noise output could be placed at the exhaust outlet.

WhatsApp: +86 18037808511

A tangential ultrasonic vibrationassisted gear grinding (TUVAGG) system was proposed in this paper to enhance the machining accuracy and performance of gears. Firstly, the longitudinal resonant vibration system of the TUVAGG was designed based on the nonresonant theory. The frequency equation and the displacement characteristics for the vibration system were obtained for the particular ...

WhatsApp: +86 18037808511

As the grinding mill vibrates, media particle migration is experienced in both axial and transverse directions. In fact, the media migrates through the VIBRADRUM® Grinding Mill in a path similar to that of a rotary grinding mill without lifters, but each media particle imparts positive impact energy at each vibration.

WhatsApp: +86 18037808511