Latest Technology of Mill Diaphragms Free download as PDF File (.pdf), Text File (.txt) or read online for free. "Latest technology of mill diaphragms" presented by: Christian Pfeiffer Maschinenfabrik GmbH Sudhoferweg 110 112 59269 Beckum Germany TABLE OF CONTENT: Introduction Requirements for a modern intermediate diaphragm Design features of modern diaphragms Support ...

WhatsApp: +86 18037808511

Mill liner wear measurement and prediction services. Back. Mill Liners. Back. Rod Mill. Back. Rotary Scrubbers. Back. ... Dorrco™ Diaphragm Pumps ... we have set a target of providing solutions for zeroemissions mining and zeroemissions cement production by 2030, supporting a green transition built upon sustainable materials. ...

WhatsApp: +86 18037808511

Earlier studies of the authors (Benzer, 2000, Lynch et al., 2000, Benzer et al., 2001a, Benzer et al., 2001b, Benzer, 2005) on industrial scale multichamber cement mills have shown that diaphragms in multichamber ball mills can be considered as a kind of classifier which is fed by the product of the first grinding chamber and produces a fine product as the feed of the second grinding chamber ...

WhatsApp: +86 18037808511

Cement mill (Ball Mill) consists mainly of : A rotation steel cylindrical shell supported at both ends on turning /. slide shoe bearings. Liners for protecting the inside surface of the shell. Diaphragms for dividing the mill into two or more compartments. Grinding Balls. Mill cooling system.

WhatsApp: +86 18037808511

diaphragm is not able to controlling the material flow. Earlier most of the mills in opencircuit, now cement plants converting to close circuiting by incorporating changes in the mill internals of liners, stanex diaphragm and outlet diaphragm including separators, fans and bucket elevators. Fig Material flow inside mill 2.

WhatsApp: +86 18037808511

INTERNATIONAL CEMENT REVIEW FEBRUARY 2021 aim of delivering a target mill discharge size at the end of the chamber, with a maximum residue of five per cent >2mm. This is a standard limit and is practically known to guarantee the coarsest grain to be <6mm a standard discharge slot size of an intermediate diaphragm. In this

WhatsApp: +86 18037808511

The results suggested that the operational capacity of cement mill of lines 1 and 2 when optimizing the process conditions increased by around and 15%, and the blaine of the final product of ...

WhatsApp: +86 18037808511

SType, L=2m S2 Cement Grade OPC grade 43 Pitot Constant L Type L Feed Product Water Mill Operation CCR Mill Feed Rate, wet tph Mill Main Drive I kW 3350 Mill Feed Rate, dry tph Mill Main Drive II kW 0 Clinker Feed Rate tph Total Main Drive Power kW 3350 Gypsum Feed Rate, wet tph Total Installed ...

WhatsApp: +86 18037808511

Whether you produce cement, industrial minerals or solid fuels: Christian Pfeiffer designs and builds grinding plants for many different feed materials and end products. Our mills are as diverse as our customers' requirements. Ball mill, roller press, vertical mill, or autogenous mill?

WhatsApp: +86 18037808511

The material is fed directly into the second chamber at the backside of the diaphragm. As a result, the effective grinding length of the mill is fully utilized. In many cases, an increase in production of 3 6% can be achieved by the intermediate diaphragm MONOBLOC.

WhatsApp: +86 18037808511

In the model structure, the last mill in the first chamber operates in closed circuit with a screen which represents the classification that occurs at the diaphragm. In . Discussion. A full model of a multichamber cement mill should contain all the design variables which have influence on the operation.

WhatsApp: +86 18037808511

Mill internals: Face and peripheral armoring Partition diaphragm Outlet wall Grinding charge Cement grinding plant with a Ø x m mill seated on shoetype bearings Two chamber mills are used for grinding cement, slag and similar materials. They are typically arranged in a circuit with high effi ciency VTP separators.

WhatsApp: +86 18037808511

Rules of thumb Raw material: 1016 kWh/t (mill motor) target fineness: passing 200µm>99%, passing 90µm>88% depending upon burnability of raw mix) Cement: For a pure cement (95% clinker) at 3500 cm2/g, the mill motor consumption should be <40 kWh/t. (Clinker grindability: approx 32 kWh/t at 3000 cm2/g (mill motor).

WhatsApp: +86 18037808511

On a process point of view, a mill inspection is only representative if the grinding mill circuit is in a steady working

. condition with a representative cement product.

. If this condition is fulfilled, the whole installation must be stopped in crashstop (it means all the equipments

. must stop at the same moment).

.

Versatile system based on standard modules The Unidan mill, type UMS, is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement and for separate dry grinding of similar materials with moderate moisture content. The mill types TMS and TUMS are fully and semi airswept mills respectively, designed for dry grinding of raw materials for cement manufacture.

WhatsApp: +86 18037808511

Cement Tube mill internals Introduction. Tube Mill Introduction: Supplies and Services for Tube Mills: Grinding Media. Shell Liners (Bolted and Boltless) Diaphragm (Drying, Intermediate and Discharge) Mill Audits. Ball Charge Management. Installation Supervision.

WhatsApp: +86 18037808511

The material is fed directly into the second chamber at the backside of the diaphragm. As a result, the effective grinding length of the mill is fully utilized. In many cases, an increase in production of 3 6% can be achieved by the intermediate diaphragm MONOBLOC.

WhatsApp: +86 18037808511

The mill shell is divided by a diaphragm. Coarse grinding using big balls of up to 100 mm in diameter takes place in the first compartment. The peripheral wear lining is designed as a lifting or activator plate lining which, ... for cement with polycom ®, ball mill and sepol ® PC.

WhatsApp: +86 18037808511

The moisture content on the kiln raw materials is also higher than the cement mill feed, which is generally dry. ... the slots of the mill diaphragm. However, topping up the mill with additional ...

WhatsApp: +86 18037808511

Cement mill 812 kWh/t. Raw mill 40 45 % of total mill power consumption. Diaphragm slot openings are : 68 mm in the first compartment. 810 mm in the second compartment. Prerequisites. Mill feedsize. Clinker and additives 95% passing 25 mm; 100 % passing 50 mm. Raw material 95% passing 30 mm; 100 % passing 50 mm.

WhatsApp: +86 18037808511

Tube Mill Internal. The tube mill internals of cement manufacturing industry is composed of the grinding media, shell liners and the diaphragm. The change in impact condition may result in either spalling or hardening of the grinding media which in turn decrease the shelf life, increase the operating cost and increase the downtime.

WhatsApp: +86 18037808511

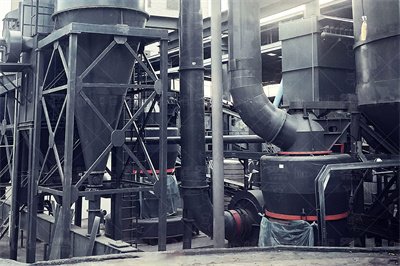

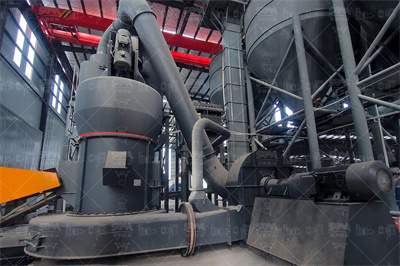

In general, cement mill can both apply for dry cement production and wet cement production. Commonly, there are three hot types of cement mill in the cement industry: cement ball mill, Raymond mill, and vertical cement mill. AGICO Cement can supply cement mill according to your requirements.

WhatsApp: +86 18037808511

Solid filtration technology for sustainable practices. As mining and other industries focus more on sustainability, they still face increasing pressure for profitability. We provide filtration technology that plays a significant role in efficient production of a quality product. Our solutions are highperformance and efficient, focused on the ...

WhatsApp: +86 18037808511

cement mill diaphragm Manufacturers, Factory, Suppliers from China. Reliable quality and good credit standing are our principles, which will help us at a topranking position. Adhering to the tenet of "quality first, customer supreme" for cement mill diaphragm, cone crusher parts, jaw crusher parts, Rod Mill Liner, Hammer Crusher Parts .

WhatsApp: +86 18037808511

BALL MILL INTERNALS. Ball Charge, Liners and Diaphragm. Melchior Buhendwa HTC Global Operational Support Cement Production Intense Training Casablanca, 15th to 19th May 2017 THE BALL MILL INTERNALS. Outlet diaphragm Intermediate diaphragm Feed Head Liners Second Chamber liners First Chamber liners. Central Screen. Slide (5); 15/5/2017; Ball Mill Internals BALL MILL INTERNALS Functions ...

WhatsApp: +86 18037808511

The internal liners and intermediate diaphragm of the ball mill are made of high chromium alloy steel, which is solid, wearresistant, and has a long service life. ... The cement ball mill is mainly composed of a horizontal cylindrical shell, feeding discharging hollow shafts, liner plates, and grinding media. The mill body is a long cylinder ...

WhatsApp: +86 18037808511

cement mill intermediate diaphragm width Grinding Mill China. Italy USA s/Germany Sudhoferweg 110112 Maschinenfabrik . Twochamber cement mill Intermediate diaphragm of 4 th generation . thickness of 8 10 mm.

WhatsApp: +86 18037808511

Ball mill diaphragm supplier AGICO CEMENT. We can customize ball mill diaphragm or other ball mill parts including ball mill girth gear, ball mill pinion, ball mill trunnion, and ball mill bearing house according to the requirements of clients. If you have any questions, welcome to ask!

WhatsApp: +86 18037808511

The discharge diaphragm allows the ground material to pass but retains the grinding balls in the grinding chamber. Christian Pfeiffer adjusts the diaphragm individually to the existing grinding plant, fixing it either on the discharge mill head or floating on the mill shell. Easier maintenance and replacement of main wear zones through division ...

WhatsApp: +86 18037808511

cement ball mill. Application: limestone, clay, coal, feldspar, calcite, talc, iron ore, copper, phosphate, graphite, quartz, slag. Capacity: .65615T/H. The cement ball mill usually can be applied to raw meal grinding or cement grinding. Besides, the cement ball mill also can be used for metallurgical, chemical, electric power, other mining ...

WhatsApp: +86 18037808511

Mill liner wear measurement and prediction services. Back. Mill Liners. Back. Rod Mill. Back. Rotary Scrubbers. Back. SAG Mill. ... Dorrco™ Diaphragm Pumps Gorator Pump KREBS® gravelMAX™ slurry and dredge pump ... For new cement plants, our process expertise and product portfolio deliver plants with the minimum environmental footprint. ...

WhatsApp: +86 18037808511

What to expect from a cement ball mill inspection. May 02, 2019. by GCP Applied Technologies. Having an independent audit of your cement mill can identify opportunities for productivity improvements, including increasing production or lowering energy consumption. It is common to achieve a 510% gain in production by following mill audit ...

WhatsApp: +86 18037808511

The discharge diaphragm allows the ground material to pass, but retains the grinding balls in the grinding chamber. Christian Pfeiffer adjusts the diaphragm individually to the existing grinding plant, fixing it either on the discharge mill head or floating on the mill shell.

WhatsApp: +86 18037808511