W = Width of HeadA = Angle ChangeC = Cut DepthC = x W x A. So, if we had a Chevrolet 23degree head with a maximum width of inches and we desired to make a 1degree change in valve ...

WhatsApp: +86 18037808511

For example, if a mill is stopped by a brake, acting on a flange integral with a segmented head, on rare occasions the brake may grip the flange just at the end of the segment. In that case, the resulting brake forces will not distribute, circumferentially, to both sides of the brake calipers, but only to one side, due to the flange split line.

WhatsApp: +86 18037808511

Position the cutter centrally over the drilled hole, with the cutter rotating, and move axially to flange depth (Z = flange height chamfer size) Feed the cutter to engage with the radius compensation (Y = hole radius) Interpolate 360. Feed back to hole centre. Retract cutter.

WhatsApp: +86 18037808511

A hydrostatic shoe bearing on a primary autogenous mill. Support ring bore 2500 mm. Front page: A Morgardshammar primary autogenous mil/ m, 3200 kW. 2 . A big spherical roller bearing (bore 1800 mm) being erected in its housing. l. I The object of the grinding process is a mechanical reduction in size of crushable material. Grinding can be undertaken in many ways.

WhatsApp: +86 18037808511

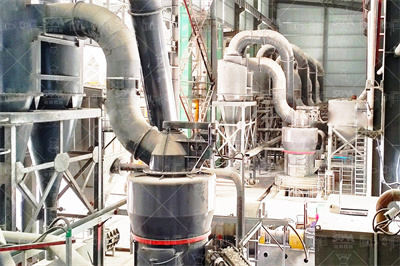

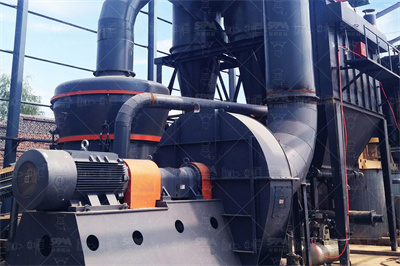

The mill produces optimumquality, highresistance cement with a lower Blaine, and enables an exceptionally high cement/clinker ratio. The FCB Horomill® helps cement producers reach sustainability goals through: The lowest energy consumption on the market (3065% energy savings compared to ball mills, and 1020% compared to vertical roller mills)

WhatsApp: +86 18037808511

Unlike a concentrator with multiple grinding lines, conducting SAG mill maintenance shuts down an entire concentrator, so there is a tremendous focus on minimizing required maintenance time; the reline timeline often represents the critical path of a shutdown (but typically does not dominate a shutdown in terms of total maintenance effort).

WhatsApp: +86 18037808511

For fast track delivery schedules, we offer a standardised series of mills known as the FT Series Grinding Mills. These FT Mills are designed in standard sizes from to meters in diameter. These designs enable quick turnaround for approval documents, improve equipment delivery, and increase parts availability. ... Fully machined flanges ...

WhatsApp: +86 18037808511

FF8200 Flange Facer; Key Mills. KM3000 Key Mill; KM4000 Key Mill; Lathes. PL2000 Lathe; PL3000 Lathe; PL4000 Lathe; Milling Machines. LM5200 Linear/Gantry Mill; ... Valve Grinding Lapping Machine VM2000 Series; Single Point Valve Repair Machines. VM8000 Globe/Control Valve Repair; Valve Testing Equipment.

WhatsApp: +86 18037808511

Step 1: Put the picked raw steel materials into a mediumfrequency furnace for melting, and raise the temperature of liquid steel to 1600℃~1700℃. Step 2: Preheat the metal mold between 800℃ and 900℃, and maintain the temperature. Step 3: Turn on the centrifuge machine, pour the liquid steel (step 1) into the metal mold (step 2).

WhatsApp: +86 18037808511

Flanges. Grinding machines shall be equipped with flanges in accordance with paragraph (c) of this section. (a)(4) Work rests. On offhand grinding machines, work rests shall be used to support the work. They shall be of rigid construction and designed to be adjustable to compensate for wheel wear.

WhatsApp: +86 18037808511

The model result is "horsepower per foot of mill effective grinding length", so multiply the result by the mill EGL to get pinion power draw. ... This flangetoflange length is usually six inches more than the EGL for overflow mills. The flangetoflange length may be anywhere between and 3 feet longer than the EGL for grate mills (more ...

WhatsApp: +86 18037808511

FF8200 Flange Facer; Key Mills. KM3000 Key Mill; KM4000 Key Mill; Lathes. PL2000 Lathe; PL3000 Lathe; PL4000 Lathe; Milling Machines. LM5200 Linear/Gantry Mill; ... Valve Grinding Lapping Machine VM2000 Series; Single Point Valve Repair Machines. VM8000 Globe/Control Valve Repair; Valve Testing Equipment.

WhatsApp: +86 18037808511

General Flange Domestic, Manufacturer, Steel, Domestic flanges. General Flange is a domestic manufacturer of flanges with precision machining capabilities.

WhatsApp: +86 18037808511

The flanges are machined in order to provide them with locating surfaces fitting into the respective heads. The shells of ball and pebble mills are provided with 2 manholes with closely fitting covers. ... Grinding Mill Support Equipment. We have has designed a series of single stage speed reducers, which makes it possible to drive the mills by ...

WhatsApp: +86 18037808511

Grinding Mill Solutions . Bradken is a leading engineered grinding mill solutions provider, supported by inhouse design and manufacture of highquality mill liner components to suit AG/SAG, Ball and Rod Mills. By utilising the latest research and technologies, we provide customers with advanced Mill Liner Solutions and products that improve ...

WhatsApp: +86 18037808511

Valve Grinding Lapping Machines. VM1150 or VM1200 Gate Valve Grinding Lapping; VM1350, VM1500, OR VM1600 GATE VALVE GRINDING LAPPING; ... FF8200 Flange Facer; Key Mills. KM3000 Key Mill; KM4000 Key Mill; Lathes. PL2000 Lathe; PL3000 Lathe; PL4000 Lathe; Milling Machines. LM5200 Linear/Gantry Mill;

WhatsApp: +86 18037808511

Clean arbor and flanges before mounting a grinding wheel. Check the mounting flanges for proper type, size, and flange condition. NEVER USE MISMATCHED, UNDERSIZE, DIRTY OR DAMAGED FLANGES. Use only machines designed and guarded for the grinding wheel you are using. NEVER MOUNT A GRINDING WHEEL ON A MACHINE THAT IS NOT DESIGNED FOR THAT GRINDING ...

WhatsApp: +86 18037808511

Due to its shape, it is called a tube mill and due to use of grinding balls for crushing, it is called a ball mill, or both terms as a ball tube mill. These mills are also designated as an example size, BBD4772,asdadasd ... The intermediate shell connects to the end shells by flange joints and the total length of shell is m. The liners are ...

WhatsApp: +86 18037808511

The most common types of CNC grinders are surface grinders, cylindrical grinders, precision ID OD grinders, and centerless grinders. 1. Surface Grinders. By far the most common grinding operation, surface grinding is a finishing process to grind a flat metal surface, providing a polished look or holding a critical dimension.

WhatsApp: +86 18037808511

Description. History. Mill was ordered but the project was cancelled prior to installation. It is stored at manufacturer warehouses or storage sites. Manufacture and Design. Grate discharge. Diameter 38′. Length 25'5″ flangetoflange. EGL 22′.

WhatsApp: +86 18037808511

Used Mills. Industrial mills are used to change the size of a product, whether by breaking or grinding a material into smaller granules or powder or by agglomerating a product into larger granules or pellets. Roller mills use rollers to crush the product into a smaller granule or powder. An attritor mill wears the product into a smaller size.

WhatsApp: +86 18037808511