CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volume.

WhatsApp: +86 18037808511

Museumsufer: Staedel was the big draw. See 717 traveler reviews, 241 candid photos, and great deals for Frankfurt, Germany, at Tripadvisor.

WhatsApp: +86 18037808511

Cement ball mills are typically two chamber mills (Figure 2), where the first chamber has larger media with lifting liners installed, providing the coarse grinding stage, whereas, in the second chamber, medium and fine grinding is carried out with smaller media and classifying liners.

WhatsApp: +86 18037808511

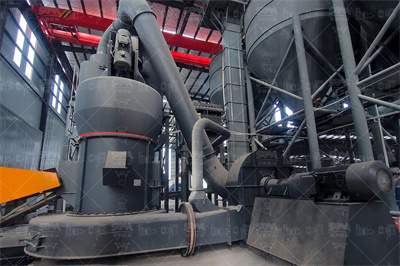

and vertical roller mill, VRM [35]. Among these devices, VRM plays an important role in cement, accounting for more than 55% of China's cement raw meal market [6], and its performance directly affects the cost of producing cement. VRM has the functions of grinding and powder selection, including a grinding unit and an air classifier ...

WhatsApp: +86 18037808511

V R Mill for grinding raw materials: 5: Dust Collector for raw mill and kiln: 6: ... Figure 4 describes the cement mill grinding process. Clinker, gypsum, and fly ash are fed to a ball mill by a feed conveyor with a certain proportion. The ball mill has two chambers. In the first chamber, the material is crushed roughly with large steel balls.

WhatsApp: +86 18037808511

For grinding cement, two types of mills are used ball and roller. Recent decades have proven the great effectiveness of a vertical roller mill for grinding raw materials.

WhatsApp: +86 18037808511

For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality. Further, our vertical roller mill solution for cement grinding has an ability to dry, grind and separate within a single ...

WhatsApp: +86 18037808511

A full cement production process includes the cement crushing process, raw mill process, clinker process, and cement grinding process, cement packing process, and related process. ... cement ball mill and cement vertical mill are ... size and dimensions, material and weight, and your drawings with details, you can send the drawing to info ...

WhatsApp: +86 18037808511

The results showed that power draw of the cement mills could accurately be predicted by the method proposed in this study. Key words: power draw, cement, dry grinding, ball mill INTRODUCTION ... electricity consumption for cement production is used for grinding the raw material and cement clinker (Zhang et. al., 1988). Annual cement production ...

WhatsApp: +86 18037808511

White cement plant in general arrangement and outline drawing of this project has been created by FLSmidth (Danish Company).The units loaded and designed under EURO CODE : 1 Raw mill building: Steel structure containing silos inside in addition to several task was design of connections and detailing.

WhatsApp: +86 18037808511

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

WhatsApp: +86 18037808511

When grinding cement, the ball mill has a yield of 300~1000g/t, and the grinding system of the roller press has a yield of /t, so it can meet the requirements of white cement. Low noise. The ball mill noise is above 110 dB, while the roller press is about 80 dB.

WhatsApp: +86 18037808511

Optimization of continuous ball mills used for finishgrinding of cement by varying the L/D ratio, ball charge filling ratio, ball size and residence time Article Dec 2004

WhatsApp: +86 18037808511

The results demonstrated that the VRM unit consumes around 81% ( kWh/t of raw materials), and 36% ( kWh/t of raw materials) more energy to grind raw material than the IBAT unit and domestic ...

WhatsApp: +86 18037808511

Generally, ball mills and vertical roller mills are used. The raw mix is dried by using part of the excess heat from the kiln in the process line or from a stove. The hot air and raw materials are simultaneously fed into the grinding position, dried, and ground. ... However, the waste gases discharged from the raw and cement mills at a ...

WhatsApp: +86 18037808511

mechanical cement plant raw mill drawing n. mechanical cement plant raw mill mechanical mounting cement mill CCM ball mill slide shoe bearing pdf ball mill operation Get Price>> maintenance slide shoe bearing cement mill can provide a set of well solution forCONCRETE BATCH PLANT MAINTENANCE AND .Lubricate packing ...

WhatsApp: +86 18037808511

The opencircuit grinding system of the ball mill is shown as follows: materials (including clinker, gypsum, mixed materials, etc.) mixed according to a certain proportion will be directly stored in the steel silo as finished cement products after being ground by the ball mill.

WhatsApp: +86 18037808511

Raw material ball mill, also called raw meal ball mill, is important grinding equipment in cement production process After being crushed, the raw meal enters the raw material mill The raw meal is grinded into fine powder by the motion and squeezing of steel balls The raw material mill manufactured by Great Wall Machinery can meet the raw material supply of 250~2500t d

WhatsApp: +86 18037808511

Cement raw materials ... According to China's economic and reasonable situation of using highquality coal to produce white cement, vertical cement mills or cement ball mills can be considered to help reduce "iron" pollution. ... material and weight, and your drawings with details, you can send the drawing to info ...

WhatsApp: +86 18037808511

Vertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing raw mill is an ideal grinding mill that crushing, drying, grinding, grading transfer set in one. It can be widely used in cement, electric power, metallurgy, chemical industry, nonmetallic ore, and other industries.

WhatsApp: +86 18037808511

Steel balls are one of the most widely used grinding media in cement ball mills, their diameters can range from 20mm to 150mm according to different grinding requirements. In a cement ball mill, generally, φ50100mm steel balls are used in the coarse grinding chamber, φ2050mm steel balls are used in the fine grinding chamber. 2. Short Cylinders.

WhatsApp: +86 18037808511

Ball Mill Drawing,Buy Quality Ball Mill Drawing from . Ball Mill Drawing, . Henan Zhongke Engineering Technology Co., Ltd. . Cement Ball Mill or dry type end product size grind cement, .

WhatsApp: +86 18037808511

India is the world's second largest producer of cement and produces more than 8 per cent of global capacity. Due to the rapidly growing demand in various sectors such as defense, housing, commercial and industrial construction, government initiative such as smart cities PMAY, cement production in India is expected to touch 550600 million tones per annum (MTPA) by the end of year 2025.

WhatsApp: +86 18037808511