A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, and ceramics. ball mills A ball mill in mining is a ...

WhatsApp: +86 18037808511

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. ... grinding equipment ...

WhatsApp: +86 18037808511

The finesse of the material milled by the ball mill is, only except for the two small ball mills that have a wider range of However, the rod mill fine grinding fineness is about In terms of the fineness of the ground material, the ball mill has a finer handling ability.

WhatsApp: +86 18037808511

The following table illustrates the action of a normal ball charge at various percentages of critical speed. Generally speaking ball mills operate within the range of 50% to 90% of critical speed. The average is found to be approximately 75%. Pebble Mills have been found to operate more efficiently at higher speeds than ball mills.

WhatsApp: +86 18037808511

AMIT 135: Introduction to Mining Systems and Equipment; AMIT 145: Introduction to Mineral Benefication; PRT 110: Introduction to Occupational Safety, Health and Environmental Awareness; PRT 140: Industrial Process Instrumentation I ... ball mill or pebble mill. AG/SAG mills can accomplish the same size reduction work as two or three stages of ...

WhatsApp: +86 18037808511

Rod mills: Rod mills are typically used in the mineral industry to grind materials to a specific size. Ball grinding millΦ×3Φ×6: ... Ball mill machines are key equipment for powder processing in various industries, including the food, pharmaceutical, and chemical industries. Understanding the components, types, and applications of ...

WhatsApp: +86 18037808511

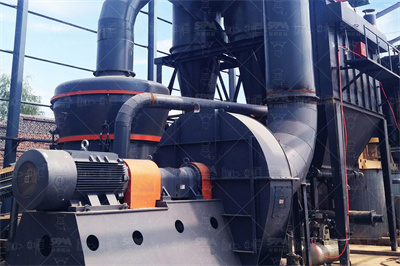

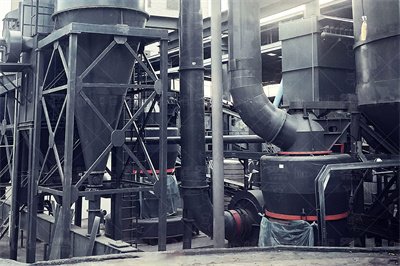

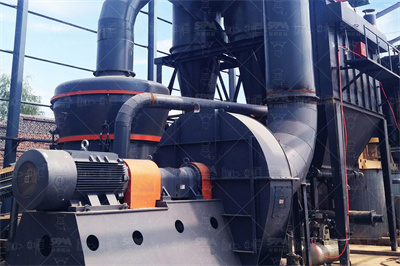

Grinding equipment. Grinding equipment is the key equipment for crushing materials after they are crushed. The ball mill can process various grinding minerals, nonferrous metal beneficiation, and new building materials. It is often combined with a spiral classifier to form a closedcircuit ring mill, which has higher fine powder and grinding ...

WhatsApp: +86 18037808511

Spiral Chute. Mixer. Grinding Steel Ball. Trommel Screen. High Efficiency Concentrator. Disc Granulator. High Frequency Screen. Pendulum Feeder. After stone crushing process, you can buy mineral processing equipment from us, starting from grinding, classification, gravity separation, flotation, magnetic separation and other ore processing methods.

WhatsApp: +86 18037808511

Contact name:lily Whatsapp: + email:lily420677 Rod mills and ball mills are the two most commonly used equipment in grinding equipment.

WhatsApp: +86 18037808511

Advanced ball mills and mineral processing equipment help mining companies around the world process minerals more efficiently. ... An iron powder ball mill is used to grind iron powder directly, as some industries don't require high iron content and prefer coarser iron powder. The iron powder ball mill grinds the iron powder to a certain size ...

WhatsApp: +86 18037808511

Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes. This grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor. While fine grinding consumes less energy than primary grinding, it can still account for a substantial part of a mill's energy budget. Overall energy use and media ...

WhatsApp: +86 18037808511

When Kincaid lignite was pulverized utilizing inthemill drying at product moisture content in the range of 11 to 12 percent, the comparison factor was for pulverization in the ball mill and in the hammermill. Power requirements at these conditions were kwhr/ton in the ball mill and about 17 kwhr/ton in the hammermill.

WhatsApp: +86 18037808511

The ball mill machines mainly include: raw mill, coal ball mill, ore ball mill, small ball mill, wet ball mill, ceramic ball mill, overflow ball mill, as well as vertical ball mill, rod mill and automatic/semiautomatic mill and other industrial milling equipment.

WhatsApp: +86 18037808511

The small ball mill is a smallcapacity grinding equipment, which is defined relative to large ball mill. It is generally suitable for smallscale production in the trial production stage. Due to its small size and easy movement, small ball mill is sometimes referred to as mobile ball mill.

WhatsApp: +86 18037808511

ball mill: [noun] a pulverizing machine consisting of a rotating drum which contains pebbles or metal balls as the grinding implements.

WhatsApp: +86 18037808511

BallRod Mills, based on 4″ liners and capacity varying as power of mill diameter, on the 5′ size give 20 per cent increased capacity; on the 4′ size, 25 per cent; and on the 3′ size, 28 per cent.

WhatsApp: +86 18037808511

A ball mill is a grinding machine used to grind and blend materials for use in mineral processing, ceramics, and pyrotechnics. The ball mill works by rotating a cylinder with steel grinding balls ...

WhatsApp: +86 18037808511

1. Fill the container with small metal balls. Most people prefer to use steel balls, but lead balls and even marbles can be used for your grinding. Use balls with a diameter between ½" (13 mm) and ¾" (19 mm) inside the mill. The number of balls is going to be dependent on the exact size of your drum.

WhatsApp: +86 18037808511

Ball mill and rod mill are the widely used equipment in mineral process plant. They have similarities in appearance and working principle, but also have much differences in the structure, performance and usage. In this article we analyze their similarities and differences from 7 aspects, it will help to choose ball mill and rod mill.

WhatsApp: +86 18037808511

Denver Equipment Company 41 14 Empire State Bldg. ILLINOIS, Chicago 1 Denver Equipment Company 112324 Bell Building 307 No. Michigun Avenue TEXAS, El Paso Denver Equipment Company UTAH, Salt Lake City Denver Equipment Company P. 0. Box 705 MEXICO, Mexico, Denver Equipment Co., 14 Avenida Juorez, Derpacho 615 CANADA, Toronto 1

WhatsApp: +86 18037808511

Xinhai provides mineral processing technology, equipment manufacture and onestop service for mineral processing plant, which solve many problems for mine investors. Xinhai equipment mainly include: ball mills, flotation, thickeners, and so on. marketing 0086 .

WhatsApp: +86 18037808511

With the continuous use of ball mill equipment, the quality of ball mill steel balls has also become a key point. The varieties specified in the national standard include chemical composition, mechanical properties, Cast ball specifications, and inspection methods, etc. Good quality grinding balls should have the following properties:

WhatsApp: +86 18037808511

Ball mill and rod mill solutions are available here at APT, providing an effective means for grinding and blending materials in preparation for mineral liberation, from rock to dust. APT specifies and designs the entire circuit around the mill, to ensure that the target product size is achieved. Ava

WhatsApp: +86 18037808511

Ball mill is the key equipment for recrushing the materials after they are primarily crushed. Ball mill is widely used for the dry type or wet type grinding of all kinds of ores and other grind ...

WhatsApp: +86 18037808511

They are highly efficient Grinding mill machines, designed for grinding applications, where fine material is required. DOVE Ball Mills are used in supplied and applicable for wet and dry grinding applications within the following branches of industries:

WhatsApp: +86 18037808511

Ball Mill Introduction . There are three main stages to mineral processing in the mining are: Comminution (crushing and grinding).; Beneficiation (separation and concentration).; Smelting and refining.; Ball mills are employed in the comminution stage as grinding machines (size reduction).The purpose of grinders in the mining industry is to reduce the feed material size in order ...

WhatsApp: +86 18037808511

Online Message. +. sale01 . TOP. Henan Bailing Machinery Co., Ltd.: As one of the China Leading professional mineral equipment manufacturers,we are mainly on jaw crusher, cone crusher, impact crusher, rotary dryer, flotation machine, ball mill beneficiation equipment. we're featured by competitive price ...

WhatsApp: +86 18037808511

Crusher and ore ball mill are the main equipment in these two stages. Working Principle of Ore Ball Mill First of all, the material is fed into the barrel from the hollow shaft feed port of the mineral processing ball mill, and then enters the inside of the ore grinding mill.

WhatsApp: +86 18037808511

Crushers, Pulverizers Mills. Particlesize reduction, or comminution, is often required to prepare bulk material samples for testing. Crushing is often the initial step with materials such as mineral ores or aggregates using varying combinations of force, impact, and compression to initiate fracturing in the materials.

WhatsApp: +86 18037808511

Mineral Mill Equipment (3481 products available) 15 TPH 2500 Mesh Micron Minerals Powder Grinding Clinker Lime Cement Mill Equipment 89, 450, Min Order: 1 set. 10 yrs CN Supplier . /5 ·

WhatsApp: +86 18037808511

Metso has over 100 years of experience in horizontal grinding mills and has always been an industryleader in innovative technology. Metso's unmatched expertise ensures delivery of your Premier™ mill or Select™ mill based on your operational needs. When choosing your equipment we not only keep in mind mill performance, but also considering ...

WhatsApp: +86 18037808511